Company Information

- TOP

- Company Information

- History

History

1950

Primary President, Yutaka Nakamura founded NAKAMURA Feather Laboratory to start with research of shuttlecocks for badminton. He invented breakthrough production method in casting to use plastic (which was new material at that time) for the shuttlecocks instead of bird's feather through trial and error.

- Historical background

He got information on badminton which is a sport originated in England while he researched "how feathers of birds can be used" for his thesis in his course at Tokyo University of Agriculture.

1951

4 patents and 23 industrial new designs applied and obtained. Awarded for Prize for Excellent Invention by the Minister of Trade and Industry.

- Historical background

- Japan-U.S. Security Treaty concluded.

How light shuttlecock can be flown straightly and slowly like bird feathers. That was what the company struggled to study shape, structure and materials.

1952

Started mass production of plastic shuttlecock: "PL-man."

"PL" in PL Man short for Paradise Lost. Paradise Lost means someone who lost hope in the paradise lost. The name was originated in the situation at that time when the company finally succeeded to realized the shuttle cock after repeating tries and errors day after day and bogging down.

1956

Reorganized to be Hatachi Industry Co., Ltd.

New building as the head office built up.

Battledores and shuttlecocks developed. But the sales was sluggish and its large inventory turned into firewood.

The patent trial for plastic shuttlecock began between Carlton, UK and us.

Recognized importance of the patent. Lots of patents on the shuttlecock and badminton racket obtained after that.

Produced 95% of plastic shuttlecocks (patented) produced in Japan.

(Ten million pieces a year)

- Historical background

- Badminton became popular and popular as one of leisure ordinary people could enjoy easily.

Thanks to the trial between Japan and England, out company was well known in sports industry and sales of the shuttle cock was driven as well as badminton was known broadly as popular sport.

Started production of wooden badminton racket. Obtained various patents on badminton rackets.

1961

The patent trial with Carlton in UK ended in reconciliation. Technological partnership with Carlton concluded. (The reconciliation was almost victory consequently).

- Historical background

- High economic growth. (10 years from 1960)

See-off to sports goods' wholesalers by he all employees from steamboat quay in front of the company.

1964

We started to export badminton rackets and shuttlecocks to the US, Canada, Australia and Europe.

- Historical background

- Tokyo Olympic Games held.

High economic growth at its peak. Tokyo Olympic Games held.

1965

New factory for wooden badminton racket built up. Specialized factory for badminton racket established in Taiwan.

1966

New factory for blow molding built up (which is blow molding factory at present).

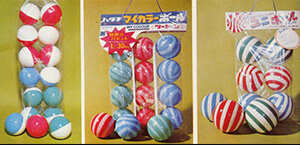

Two colors available molding machine (patented) introduced from Denmark.. "UNIBALL" production and sale started using materials of Idemitsu Petrochemical.

1967

New factory for injection molding built up. The racket factory extended.

1970

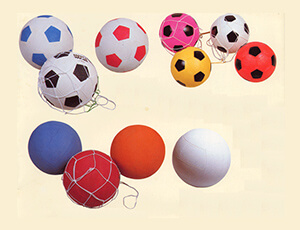

Rotational molding machine introduced, which produced dodge ball, etc.

- Historical background

- Osaka World Expo.

1973

The patent related Shuttlecock expired. Our sales declined due to cheap shuttlecock coming from Taiwan. The injection molding machine and blow molding machine were turned into the manufacture of automobile parts.

The material of badminton racket was shifted from wood to metal frame, which made sales of the wooden rackets sluggish.

- Historical background

- Oil shock.

Although the wooden-working factory was opened, it was virtually doing none at all. After that, the material revolution for rackets realized from aluminum to FRP. Now YONEX has dominated the market.

1977

Exclusive licensed patent for double-wall blow molding obtained. The double blow molded case was adopted for YAMAHA' pianica and hit much popularlily.

Due to sluggish sales of the sports goods, we were searching for new businesses. Idemitsu Petrochemical Co., Ltd. introduced Mr. Teraoka and we introduced double blow molding technology.

1979

"Hatachi Kako Co., Ltd." was established independently as a double blow molding factory and its new factory was built up.

1981

The 2nd factory of Hatachi Kako Co., Ltd. was completed. 120 mm scaled large blow molding machine introduced which was able to mold 251-L tank of Yazaki's "Yu Waiter".

In order to shift from sporting goods to industrial products business, we invested much more than our financial capability so our financing was hard to be maintained.

1982

Large-sized vacuum molding machine introduced in Hatachi Industry Co., Ltd. to manufacture large housing components.

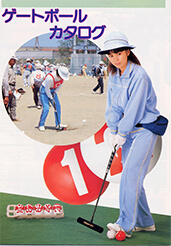

Hatachi Industry Co., Ltd. entered gate ball (Japanese croquet) market. Patents for the ball, stick, etc. obtained. The racket factory tuned into gate ball factory. The coating line set up as well.

1984

Automobile blow bumper was mass-produced firstly in Japan in Hatachi Kako by double blow molding.

- Historical background

- Plaza Accord (September 1985)

Rapid appreciation of the yen

Success of the Japan's first blow bumper was realized by development of the special blow materials n cooperation of Mitsubishi Petrochemical Corp.

1987

Produced Yamaha's wooden tennis rackets

The materials for tennis rackets were shifted to aluminum and wood. Although once Yamaha's technology which the racket was coated with thin skin of genuine was adopted for the mass-production, it was temporal and the production was shifted to Taiwan. The material was shifted to carbon after that.

1989

"Safety bamboo sword "of Hatachi Industry Co., Ltd. was selected for Good Design Product. Patents for leather patch equipped on head of the sword and production of bamboo blades obtained. Although the company proceeded with production and sales of the sword, martial art traders argued with such bamboo sword because the unbreakable one threaten sales of them. Consequently, the sales channel was difficult to be developed and the company was withdrawn from the market.

Yukio Nakano was inaugurated as the president at Hatachi Kako Co.Ltd. and Hatachi Industry Co., Ltd.

- Historical background

- Burst of Japan's economic bubble (2008), the fall of the Berlin Wall, dissolution of the Soviet Union, the end of the Cold War

1992

2nd factory extended a building at Hatachi Industry Co., Ltd., introducing large-sized blow molding machine.

1993

The Chairman Yutaka Nakamura awarded for the Governor Rewards and meritorious person in R&D.

Developed "shower helper (Shower device for nursing care)" and entered into nursing-care bath field.

1994

Hatachi Kako acquired the license for super blow molding technology.

1995

120 mm molding machine introduced, which dedicated for large-sized super blow molding.

- Historical background

- Hanshin-Awaji Earthquake disaster, a series of serious crimes by Aum Shinrikyo members

1996

Super blow molding was adopted for ceiling of unit bath.

Established overseas subsidiaries "THAI HATACHI CO., LTD." In Thailand. The company was dormant by 2000 due to the Asian currency crisis from the following year. it restarted the operation since 2001and works for molding automobile related components(air duct, tank, thermosetting resin molded pulley cam).

1997

Completed the 3rd factory of Hatach Industry Co., Ltd.

Sports Business Department of Hatachi Industry entered into ground golfing and park golfing market.

- Historical background

- Asian monetary crisis.

While popularity of gate ball was dropped, in order to enter into ground golfing market that number of players was increasing, we applied for entry as the new manufacturer into the Ground Golf Association (ASICS set up for encouraging the market) and we were approved for the entry.

2001

Tetsuya Nakamura was inaugurated as the president at Hatachi Kako Co.Ltd.

2003

135 mm extra large-sized blow molding machine introduced in Hatachi Kako. Acquired ISO 9002.

2004

Completed warehouse for molding in Hatachi Kako.

Hatachi Industry entered into welfare market.

Proposed game for preventing dementia and recreation kit as recreation for welfare facilities. Distributed direct-mail for the facilities.

2005

Hatachi Kako approved for its management reform plan by Shizuoka Pref.

Hatachi Industry started "Self-sustained physical fitness training in cooperation with Shizuoka University.

2006

Succeeded in automation of spoiler sanding process.

2007

Succeeded in automation of blow molding of burr finishing by laser processing.

Hatachi Industrial Co., Ltd. completed the factory of large-sized injection molding machine.

Hatachi Industry entered into healthcare market.

Development of health solution products for young generation.

2008

1300t bicolored injection molding machine introduced in Hatachi Industry Co., Ltd.

Participated in Brain Science Association in research of Dementia prevention tool "Noh Genki".

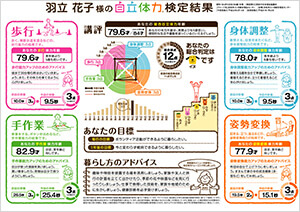

Developed "Self-sustained physical fitness test" to measure physical fitness for aged people in cooperation with Shizuoka University

Hatachi Industry entered into walking market.

- Historical background

- Global recession due to financial crisis originated from the subprime mortgage.

Proposed better walking with walking life style to the promoting parties, distributors and consumers based on Nordic walk.

2009

New collaboration plan "Development and commercialization of fuel tank with high gas barrier properties" approved by Kanto Bureau of Economy.

Hatachi Industry Co., Ltd. announced "self-reliance physical fitness test".

Measure physical fitness seen from daily lives activities.

Hatachi Industry Co., Ltd.introduced two 130-ton 2 color injection molding machines to start production of hobby related parts.

2010

Hatachi Kako Co. introduced multilayer blow molding machine.

"Development of multilayer blow molding technology for interlayer to be laminated with ultra thin conductive material (CFRP etc.)" adopted as Supporting-Industry.

2011

Completed Hatachi G Factory

Hatachi Industry started "National self-sustained physical fitness test".

"Decline of physical fitness", that may be progressed while you don't pay attention to that. This is the system to measure it both objectively and periodically analyze it totally taking questionnaires for life style into account.

Hatachi Industry Co. released the replaceable-pole cap for Nordic walk, "Fit type".

Rubber attached to top on the pole of the cap for Nordic walk. New pole cap which enables response to various scenes including training and rehabilitation.

Withdrawn from badminton business.

- Historical background

- The Great East Japan Earthquake occurred.

Events tended to be stopped and people did to refrain from shopping.

- Historical background

- Flood occurred in Thailand.

All facilities of THAI HATACHI were submerged and suffered due to flood which started from July for 3 months in the year. Also the damage impacted the business so much afterwards .

2012

Technical support agreement concluded with NTF India.

Hatachi Kako Co., Ltd. adopted domestic investment promotion project.

Established HATACHI(THAILAND) CO., LTD.

Hatachi Industry CO. acquired ISO 9001.

2013

Hatachi Industry CO. released replaceable-pole cap for Nordic walk "Lifeline-boots-type".

Aggressive type of replaceable pole cap for Nordic walk pole. The replacement timing can be seen at glance thanks to the two-tone color.

Hatachi Kako Co., Ltd. was certified as a business operator for :of specific research and development plan based on the Act on Advancement of Basic Manufacturing Technology for Small and Medium Enterprises.

G Factory introduced large super blow molding machine.

Both Hatachi Kako Co., Ltd. and Hatachi Industry Co., Ltd. adopted manufacturing assistance project.

Hatachi Industry developed "Locoretch" which is product to be measure for locomotive syndrome.

To propose products and training methods focusing on "Moving joints" and "Health maintenance training".

2015

Hatachi Industry received the 4th "Extend healthy life expectancy" award.

Awarded prize of excellence for "Smart Life Project" of national movement initiated by Ministry of Health, Labor and Welfare in the field of care prevention/supporting aged people's lives.

2016

Hatachi Industry started "Well-Smile Promotion" which promote enhancement of health.

2017

Developed and launched a new fitness design "Relaxing Work." to propose lives styles and self-realization.

Hatachi Industry assigned its injection molding business to Hatachi Kako.

2018

Adopted as "Small and medium enterprise overseas deployment support project" by Japan International Cooperation Agency (JICA).

Implemented self-physical fitness program in Thailand.